Understanding "Drift" in Food Safety Non-Conformance: Keeping Food Safety Audits In Scope

31 May 2025

Discover how "drift" in food safety audits leads to invalid non-conformances. Learn to stay in scope with food safety solutions for effective food safety culture.

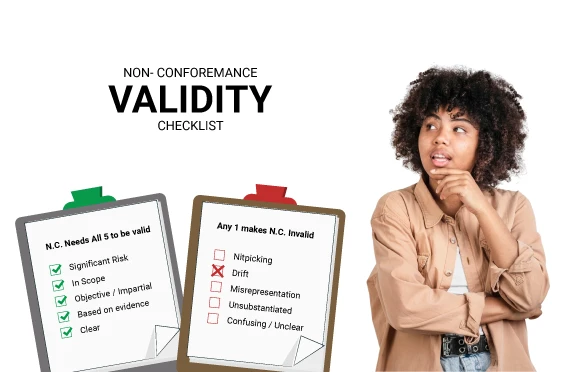

In our series on what makes a non-conformance valid or invalid during food safety audits, we’re diving into a critical issue known as "drift." Understanding drift is essential for ensuring a robust food safety culture and effective food safety solutions. But what is drift, and how does it impact food safety non-conformance findings?

What Is Drift in a Food Safety Audit?

Drift occurs when an auditor applies a standard that doesn’t align with the specific context of the food safety audit. This misapplication creates invalid non-conformances, diverting focus from genuine food safety issues. Drift often stems from where irrelevant criteria are enforced, undermining the audit’s purpose.

Common examples of drift include:

Cross-Standard Misapplication: e.g. Enforcing FSSC rules in a BRC, SQF, or IFS food safety audit.

Regulatory Misapplication: Applying Country A’s regulations to a facility not exporting there, creating an invalid food safety non-conformance.

Category Misapplication: Enforcing dairy or meat microbial controls on baking or canning operations.

Staying "In Scope" vs. Drifting during Food Safety Inspections

The opposite of drift is staying "in scope." A valid non-conformance adheres strictly to the relevant standards for the audited facility. Staying in scope requires auditors to maintain vigilance and deeply understand the applicable food safety standards, ensuring every non-conformance is relevant and actionable.

This focus is critical during food safety inspections, where missteps can lead to wasted resources and missed opportunities to strengthen programs and food safety culture.

Why Recognizing Drift Matters for Food Safety Solutions

Addressing drift in food safety non-conformances is vital for several reasons:

Relevance: Ensuring non-conformances align with the correct standards keeps audits focused on true food safety risks.

Resource Allocation: Avoiding drift prevents wasting resources on irrelevant issues, optimizing your food safety solutions.

Effective Audits: Eliminating drift enhances audit accuracy and supports HACCP certification compliance.

By recognizing drift, you empower your team to respond to invalid non-conformances during food safety audits with confidence and precision.

Enhance Your Skills with Food Safety Audit Training

To deepen your understanding of recognizing drift and ensuring non-conformances stay in scope, explore our food safety audit training course, “How to Write a Valid Non-Conformance.” This free, one-hour online training provides practical examples and insights for ensuring non-conformances stay in scope. Participants earn a certificate, supporting their HACCP certification journey and meeting food safety training requirements.

Register here: bit.ly/valid-nc

This food safety audit training benefits auditors and auditees alike, fostering clear expectations, improving communication during the audit and building a stronger food safety culture. We offer it free to advance our mission of eliminating invalid non-conformances.

Continue Exploring Food Safety Non-Conformance

Drift is one of five attributes that can invalidate a non-conformance. Dive deeper into food safety solutions with our related blog series:

Understanding Valid & Invalid Non-Conformances in Food Safety Audits [link]

Identifying Nitpicking in a Food Safety Non-Conformance: Why Not Every Finding Matters

Stay tuned for:Ensuring Non-Conformances Are Substantiated: The Importance of Objective Evidence

The Need for Clarity in Non-Conformances: Avoiding Confusion

When Food Safety Audit Reports Don’t Match Reality: Tackling Misrepresentation

By ensuring findings stay in scope and addressing drift, you can ensure your food safety inspections and audits are accurate, relevant, and aligned with driving a stronger food safety culture.