Understand Non-Conformances in Food Safety Audits

14 Jul 2025

Non-conformances (NCs) are a crucial aspect of food safety audits, highlighting areas where processes or practices do not meet required standards or risk is not being managed. However, not every NC recorded during an audit is valid. Even with professional food safety internal auditor training or HACCP auditor training, errors can occur. These mistakes may lead to invalid NCs that result in unnecessary work and wasted resources if acted upon by the manufacturer.

Why Some Non-Conformances Are Invalid

The validity of an NC isn’t guaranteed simply because it has been documented. Various factors can contribute to invalid NCs, such as:

Misinterpretation of standards

Incorrect observations

Documentation errors

These errors can create confusion, divert focus from critical issues, and complicate non-conformance food safety processes.

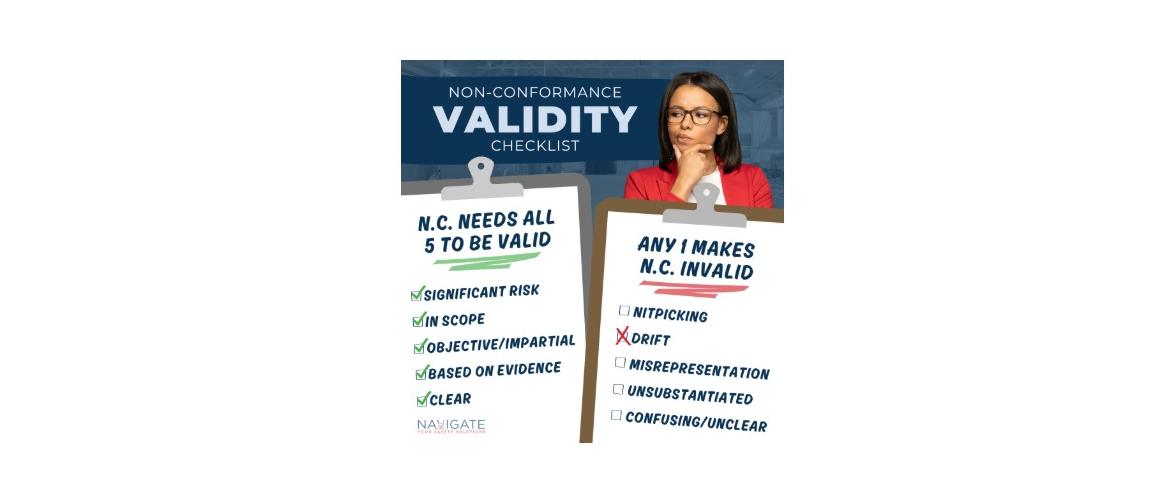

A Checklist for Validating Non-Conformances

Validating NCs is essential to ensure that resources are allocated effectively. Whether you’re preparing for an audit, conducting internal food safety auditor training, or reviewing past NCs, use this checklist to determine their validity:

Significant Risk: Does the NC identify a critical issue, or is it nitpicking?

In Scope: Is the NC relevant to the audit’s scope?

Impartial: Does the NC present all relevant facts without bias?

Based on Evidence: Is there clear, objective evidence supporting the NC?

Clarity: Is the issue clearly described, making it easy to understand and act upon?

If an NC meets these criteria, it is valid and requires action. If it fails any of these points, it is invalid and should be reconsidered.

Handling Invalid Non-Conformances

Addressing invalid NCs appropriately ensures your food safety audit services and resources are not misdirected. Here’s how to handle invalid NCs:

Reassessment: Review the NC to determine if it can be revised to reflect a genuine issue.

Dismissal: If the NC is fundamentally flawed, dismiss it to avoid unnecessary corrective actions.

Misallocating resources to invalid NCs detracts from addressing valid concerns within your food safety management system.

Further Training and Resources

For those looking to enhance their understanding of NCs, food safety auditor training courses provide essential skills. Our free training module, "How to Write a Valid Non-Conformance," is ideal for anyone involved in writing or reviewing NCs. It complements our accredited food safety Lead Auditor Training and Internal auditor training programs.

This training equips participants to:

Differentiate valid from invalid NCs

Construct clear, actionable food safety non-conformance report templates

Challenge invalid findings effectively

By investing in Accredited HACCP Training and Internal Auditor Training, you can strengthen your team’s audit skills and ensure better compliance outcomes.

Stay Tuned for More Insights

This blog is part of a series exploring key aspects of food safety auditing, including:

Identifying Nitpicking in a Non-Conformance: Why Not Every Finding is Significant

Understanding "Drift" in Non-Conformances: Keeping Audits In Scope

Ensuring Non-Conformances Are Substantiated: The Importance of Objective Evidence

The Need for Clarity in Non-Conformances: Avoiding Confusion

For expert guidance on food safety audit training, internal audit training, Accredited HACCP training, or consultancy, contact us today.